Introduction to Structural Steel Welding

Structural steel welding is a pivotal process in the construction industry, ensuring that buildings and structures are strong, safe, and durable. As engineers and builders seek reliable solutions, understanding structural steel welding techniques becomes essential. This comprehensive guide delves into the nuances of structural steel welding, exploring its significance, equipment needs, benefits, challenges, and future trends. Whether you are a novice or an expert, this article aims to enhance your proficiency in steel welding practices.

Understanding Structural Steel Welding

At its core, structural steel welding is the procedure of fusing steel components together to create load-bearing structures. This process employs various welding methods to join pieces of steel, ensuring the integrity of structures ranging from high-rise buildings to bridges. The techniques adopted in structural steel welding vary depending on the type of project, the specific properties desired in the welds, and the environmental conditions under which welding occurs.

The Importance of Structural Steel Welding in Construction

The construction industry heavily relies on structural steel welding due to its capacity to create robust frameworks. In modern architecture, where design complexity and material efficiency are critical, welding offers a stronger joint than bolting or riveting, resulting in reduced weight and increased stability. Furthermore, the ability to customize the shape and size of welded components allows architects and engineers to innovate continuously, pushing the boundaries of conventional design.

Common Types of Structural Steel Welding Techniques

Several welding techniques are prominent in the realm of structural steel welding:

- Mig Welding (Gas Metal Arc Welding): This method uses a continuous wire feed as an electrode and is suitable for various thicknesses of steel.

- Tig Welding (Gas Tungsten Arc Welding): This technique delivers precision, making it ideal for thin materials and high-quality welds.

- Stick Welding (Shielded Metal Arc Welding): Popular in outdoor construction, stick welding is versatile and cost-effective, particularly for heavy steel structures.

- Submerged Arc Welding: This method is known for its high efficiency and is primarily used in large projects requiring deep penetration welds.

Essential Equipment for Structural Steel Welding

Welding Tools and Their Functions

The right equipment can significantly impact the quality of steel welds. Essential tools include:

- Welding Machine: The heart of the welding operation, selecting the appropriate type (MIG, TIG, stick) based on the project requirements is crucial.

- Electrodes: The composition of the electrode must match the base metal to ensure compatibility and strength in the welded joint.

- Welding Torch: Essential for both MIG and TIG welding, it delivers the welding current properly to the workpiece.

- Welding Table: A stable and flat surface ensures accurate positioning and alignment of steel components.

Safety Gear for Environmental Protection

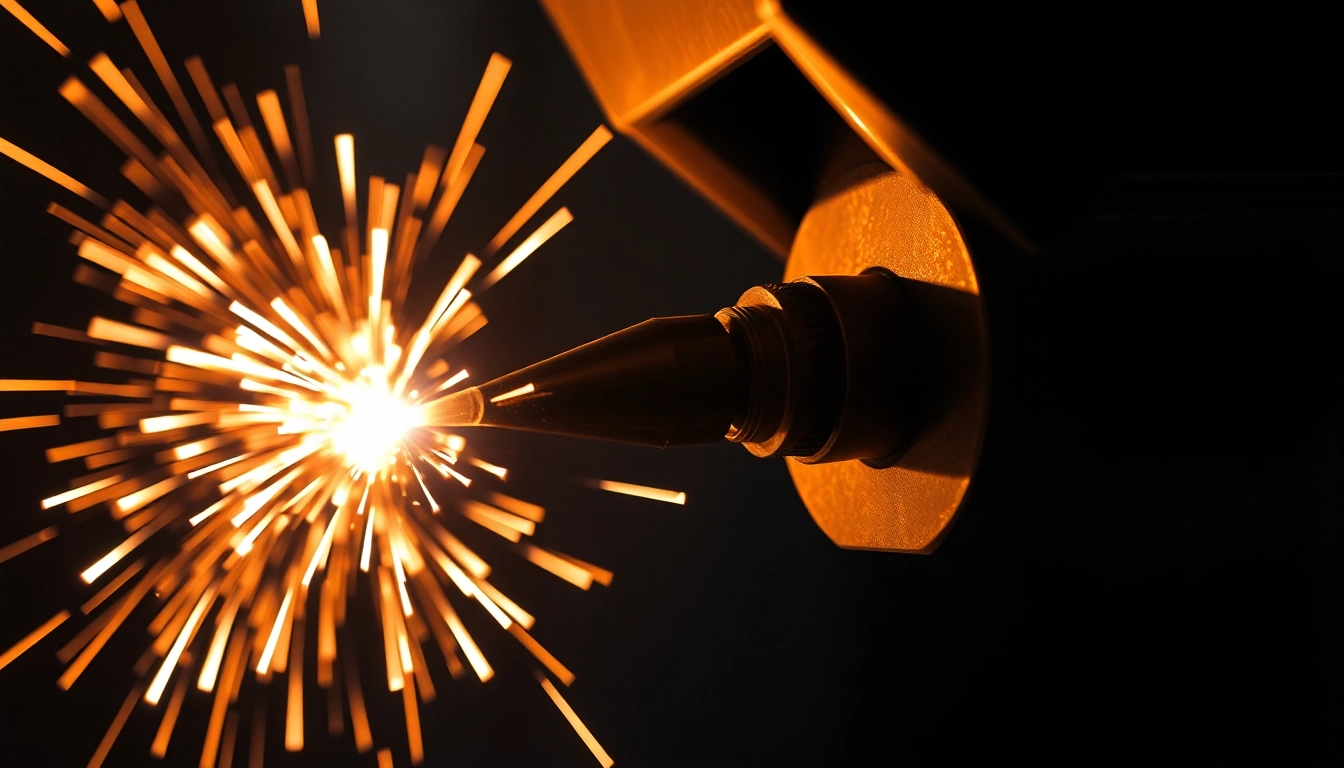

Safety in welding cannot be overstated, as the process involves hazards such as fumes, sparks, and heat. Essential safety gear includes:

- Welding Helmet: Protects the eyes and face from harmful light radiation and sparks.

- Protective Clothing: Flame-resistant jackets and gloves to shield against burns and electric shocks.

- Respirators: Essential for preventing inhalation of harmful fumes and gases emitted during welding.

Choosing the Right Welding Machine for Structural Steel Welding

Choosing an ideal welding machine depends on several factors, including the type of welding, the thickness of steel being welded, and the nature of the project. Key considerations involve:

- The power source (AC or DC).

- The machine’s amperage range.

- Portability features for job site mobility.

Investing in high-quality machines can significantly enhance welding performance and reduce project costs associated with rework.

Benefits of Professional Structural Steel Welding

Durability and Strength in Construction Projects

One of the most significant advantages of professional structural steel welding is the enhanced durability it offers. When executed correctly, welded joints are more robust and can withstand the stresses that buildings are subjected to over time. This resilience enables structures to endure environmental changes and load variances without compromising their integrity.

Cost-Effectiveness Over Time

While initial costs may seem higher for professional welding services, the long-term benefits often outweigh these expenses. Quality welds reduce the need for maintenance and repairs, as well-constructed steel frameworks have a longer lifespan. Firms experienced in structural steel welding can also minimize material waste, further lowering costs.

Enhancing Project Efficiency Through Skilled Welding

Efficiency in project timelines is crucial in the construction industry. Professional welders provide quick, high-quality services that keep projects on schedule. Their expertise ensures that welding processes are carried out with precision, making the overall workflow smoother and more coordinated.

Challenges in Structural Steel Welding

Common Issues Faced by Welders

Despite advancements, structural steel welding presents several challenges:

- Weld Defects: Issues such as cracks, porosity, and incomplete fusion can arise if proper techniques are not applied.

- Heat Affected Zones (HAZ): These areas may undergo unwanted microstructural changes, affecting the steel’s mechanical properties.

- Environmental Factors: Variables like wind and rain can disrupt the welding process, potentially leading to subpar welds.

Preventative Measures and Solutions

To mitigate these challenges, implementing a series of best practices is crucial:

- Conducting thorough pre-weld inspections.

- Choosing appropriate filler materials and welding processes that suit specific structural requirements.

- Ensuring adequate training for welders to recognize and adapt to site-specific challenges.

Staying Updated with Welding Standards and Regulations

The welding industry is subject to various standards and regulations designed to ensure safety and quality. Keeping abreast of developments in these standards, such as those outlined by the American Welding Society (AWS) and other regulatory bodies, is essential for any professional in the field. Regular training and certifications not only enhance a welder’s skills but also align practices with industry expectations.

Future Trends in Structural Steel Welding

Technological Advancements in Welding Equipment

The landscape of structural steel welding is evolving, influenced by technological advancements. Automation and robotics are beginning to play significant roles in improving productivity and accuracy in welding operations. Furthermore, innovations such as laser welding and friction stir welding are gaining traction, offering new possibilities in the joining process.

Sustainable Practices in Structural Steel Welding

Sustainability is becoming increasingly important in construction practices. The implementation of greener welding processes aims to reduce waste and environmental impact. This involves using energy-efficient welding machines, reducing emissions, and employing recycling methods for scrap metal produced during welding.

Skill Development and Training for Future Welders

The future of structural steel welding lies in the hands of the new generation of welders. Emphasizing skill development through enhanced training programs and apprenticeships can ensure a steady influx of qualified professionals. Educational institutions and organizations should focus on integrating new technologies and methodologies into their curricula to prepare future welders for the challenges ahead.