What is Machine Vision?

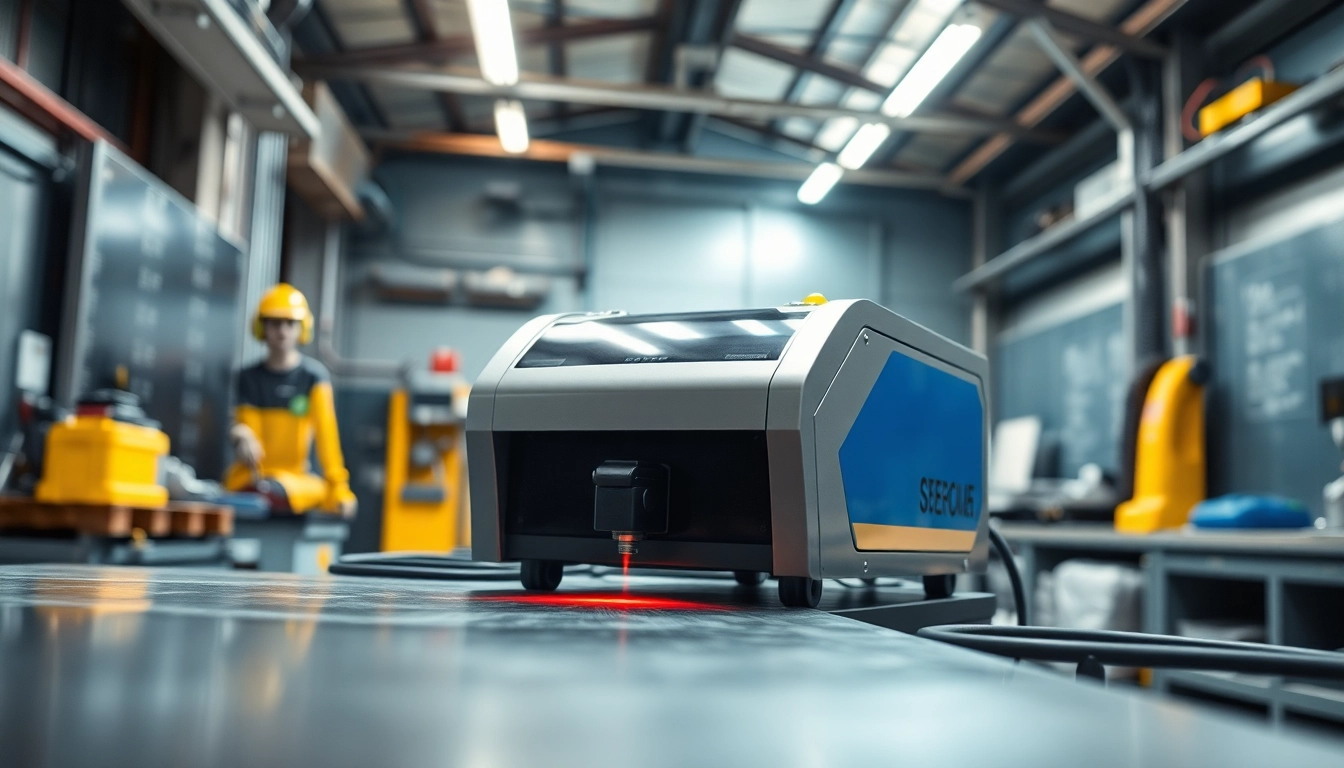

Machine vision is a cutting-edge technology that enables machines to interpret and analyze visual information from the surrounding environment. This field merges mechanical engineering, computer science, optics, and artificial intelligence to automate visual inspection processes and facilitate decision-making. The advent of machine vision has revolutionized numerous industries, enabling machines to perform tasks that historically required human intervention, enhancing efficiency, and improving accuracy in various applications.

Definition and Key Components

At its core, machine vision involves the use of cameras, lighting systems, and sophisticated algorithms to capture and process images. The definition encompasses three primary components:

- Image Acquisition: This is the first step, where cameras and sensors capture visual data. Depending on the application, cameras can range from simple 2D models to complex 3D stereoscopic systems.

- Image Processing: After acquisition, the images are processed using software that employs algorithms to analyze the visual data, identify patterns, and extract meaningful information.

- Decision Making: The final stage involves analyzing the processed data to make informed decisions regarding quality control, defect detection, or operational guidance.

How Machine Vision Works

The operation of machine vision systems involves several sophisticated technologies. Image acquisition begins with capturing raw data through various types of cameras—ranging from line scan cameras suitable for continuous monitoring to area scan cameras for capturing images of objects in motion. The choice of camera depends on the specific industrial application. Lighting plays a critical role as well; proper illumination techniques enhance image contrast and quality, enabling better analysis during the image processing phase.

Once the images are acquired, image processing techniques kick in. The images undergo filtering, enhancement, and segmentation to isolate relevant features. Advanced machine learning algorithms further enable the system to classify objects, detect anomalies, and make precise measurements, ultimately driving the decision-making process.

Applications in Various Industries

Machine vision finds applications across multiple sectors, reflecting its versatility. Some notable applications include:

- Manufacturing: In assembly lines, machine vision systems are used for quality control, ensuring that each product meets established standards by inspecting the integrity, dimensions, and presence of specific features.

- Aerospace: Aerospace manufacturers employ machine vision for precise inspections of components, ensuring safety and compliance with rigorous industry standards.

- Healthcare: Medical imaging systems utilize machine vision for assisting in diagnostic procedures, such as analyzing x-rays or MRI scans.

- Food and Beverage: Automated inspection systems guarantee packaging integrity and product quality by detecting contaminants or defects in food products.

Types of Machine Vision Systems

1D, 2D, and 3D Systems

Machine vision systems can be categorized into three main types:

- 1D Systems: These systems analyze linear features in images, typically used in barcode scanning and surface inspections.

- 2D Systems: 2D machine vision uses standard cameras to capture flat images for inspecting surface defects, measurement, and optical character recognition.

- 3D Systems: 3D machine vision adds depth perception, allowing for the examination of complex shapes and profiles, crucial in scenarios like robotic picking or assembly line navigation.

Comparing Machine Vision and Computer Vision

While often used interchangeably, machine vision and computer vision diverge in purpose and application. Machine vision focuses predominantly on industrial applications, such as inspection and automation processes, whereas computer vision encompasses a broader spectrum of tasks including image analysis for surveillance, social media, and augmented reality.

In machine vision, the systems are explicitly designed to maximize performance in specific industrial environments. In contrast, computer vision addresses a wider array of visual data interpretations, such as recognizing human emotions or analyzing video footage. Understanding these distinctions is vital when choosing the appropriate technology for specific applications.

Choosing the Right System for Your Needs

Selecting the right machine vision system involves a thorough analysis of your operational requirements:

- Assess your operational environment: Consider factors such as lighting conditions, space constraints, and the nature of the products being inspected.

- Define your objectives: Whether it’s enhancing quality control, automating processes, or analyzing data, clear objectives will guide system selection.

- Evaluate system capabilities: Look for features like resolution, speed, and processing power to ensure compatibility with your needs.

Benefits of Implementing Machine Vision

Increased Efficiency and Accuracy

One of the predominant advantages of implementing machine vision systems is the significant boost in efficiency and accuracy. Automated visual inspections can operate continuously, unimpeded by fatigue or inconsistency that may affect human inspectors, leading to enhanced throughput and quality of production.

Moreover, machine vision systems swiftly process visual data, making real-time decisions that can prevent defective products from advancing through pipelines, thus reducing the costs associated with rework and scrap. This substantially elevates operational efficiency and product standardization.

Cost Reduction and ROI

Employing machine vision can yield considerable cost savings over time. Although initial setup costs may be significant, the long-term benefits often overshadow those investments:

- Reduced Labor Costs: By automating visual inspections, companies can decrease labor costs associated with manual inspection and increase workforce specialization.

- Minimized Waste: Enhanced accuracy and early detection of defects lead to lower waste levels, fostering sustainability and improved resource allocation.

- Improved Product Yield: Consistently high-quality output contributes to improved customer satisfaction and better brand reputation, driving revenue growth.

Quality Control and Compliance

Maintaining consistent quality is critical across all sectors, and machine vision systems play an integral role in achieving compliance with regulatory standards. By incorporating automated inspection systems, industries can ensure that only products meeting quality specifications reach the market.

Moreover, these systems generate comprehensive data that can assist organizations in analyzing performance metrics, identifying root causes of defects, and refining production processes to further enhance quality assurance efforts.

Challenges in Machine Vision Adoption

Technical Limitations and Solutions

Despite the numerous benefits that machine vision systems provide, challenges persist, particularly regarding technical limitations:

- Lighting Variability: Inconsistent lighting can affect image quality. Employing controlled lighting setups can mitigate this issue.

- Image Quality: Low-resolution cameras may fail to capture the necessary detail for accurate analysis. Investing in high-resolution cameras can alleviate this problem.

- Complexity of Algorithms: The implementation of machine learning algorithms can be challenging. Collaborating with technology providers that offer expertise in machine vision solutions can assist in overcoming this hurdle.

Integration with Existing Processes

Integrating machine vision systems with existing workflows can pose its own challenges. Businesses may encounter resistance from employees accustomed to traditional methods. A change management approach that involves training programs and clear communication regarding the benefits of machine vision can enhance acceptance and facilitate smoother transitions.

Training and Skills Development

To maximize the potential of machine vision systems, organizations must invest in training employees to effectively utilize these technologies. Developing a comprehensive training program focused on both the operational aspects and technical skills will empower the workforce and optimize system performance.

Future Trends in Machine Vision Technology

Emerging Technologies and Innovations

The future of machine vision is promising, driven by numerous technological advancements. Developments in artificial intelligence and machine learning will result in more intuitive systems capable of analyzing complex data in real-time, enabling further refinement in processes.

Additionally, increased integration of sensors, including LiDAR and infrared imaging systems, will expand the application scope of machine vision, enabling more nuanced interpretations of environments and processes.

Impact of Artificial Intelligence

Artificial intelligence is poised to revolutionize machine vision by enhancing data processing capabilities. By leveraging machine learning algorithms, systems will be able to adapt to new challenges, learn from prior experiences, and make predictive analyses, ultimately leading to more streamlined operations.

Furthermore, AI-driven innovations will allow for the development of systems that can recognize patterns and characteristics not easily identifiable through conventional inspection methods.

Preparing for Machine Vision Advancements

As the landscape of machine vision evolves, organizations must remain proactive in their adoption strategies:

- Constantly assess technology developments and evaluate their applicability to existing systems.

- Engage in continuous training and skills enhancement to ensure staff is equipped to leverage innovations effectively.

- Collaborate with technology vendors to explore the latest advancements and how they can be integrated into operational frameworks.

In conclusion, machine vision represents a transformative force across multiple industries, delivering enhanced efficiency, cost reductions, and superior quality control. As organizations continue to innovate and adapt to emerging technologies, the full potential of machine vision will undoubtedly reshape the future of automation and operational excellence.